Aloha Synthetics has been providing business consultation, fleet management and maintenance scheduling optimization for over 15 years. As vehicle and machinery technology changes, Louie Agard continues to stay abreast of the latest and most critical information to keep his customers’ fleet vehicles, industrial equipent and special application machinery running at peak performance. Aloha Synthetics is listed on the amsoil.com website as an authorized Amsoil dealer on Oʻahu.

Understanding that trucks in the shop means lowered productivity, Aloha Synthetics can provide your company increased wear protection from your current lubrication products, fewer oil changes due to extended drain interval and in many cases you can use the same shop to do the work. Amsoil’s superior performance assures your fleet vehicles and heavy equipment are afforded the best protection available and reduced oil changes means real savings for you on the front and the back end. Amsoil 100% synthetic lubricants are recommended for both gasoline and diesel applications as well as specialty applications such as hydraulics and food manufacturing equipment.

On the vehicle maintenance side of things Amsoil excels by providing shop owners, managers and mechanics with competitively priced products allowing them to exceed the expectations of their customers while continuing to provide their core suite of service offerings and increasing profitability with a product that performs much better than conventional oil.

Amsoil product performance and warranties are guaranteed. Please click here for their Warranty and note that using Amsoil does not void any manufacturer warranties as long as you are using the appropriate product for your application.

Oil Change

The standard charge for a five quart oil and filter change is $35.00 to $40.00 plus tax. Driving 15,000 miles in a year and changing your oil at 3,000 mile intervals requires five oil changes at a minimum of $36.69 each which will cost you $183.49 a year. Amsoil’s Signature Series or 25,000 mile oils (15,000 miles if used in severe driving conditions) costs $60.00 for five quarts of oil and another $20.00 for a filter. Paying the same $36.69 to whoever changes your oil now results in a total annual cost of $116.69, a savings of $66.80.

Fuel savings are also a benefit of using Amsoil. Using Amsoil will give you up to a 5% improvement in gas mileage (MPG) depending on how the vehicle is driven and the conditions the vehicle is driven in.

Downtime reduced 80% by changing oil once rather five times. How many man-hours do you loose per oil change? What does that cost your company?

Waste reduced 80% by contributing 5 quarts of oil rather than 25 to the waste stream annually per vehicle.

Impressed? Probably not, however, the next time you review your income statement and are looking for significant negative variances of 3% or more, add up the projected savings from fuel and oil changes by using Amsoil, multiply by your fleet size, then compare the result to your budgeted amount for equipment servicing. You will probably find a budget item that can be improved immediately by changing only one thing in your maintenance protocol – the oil you use.

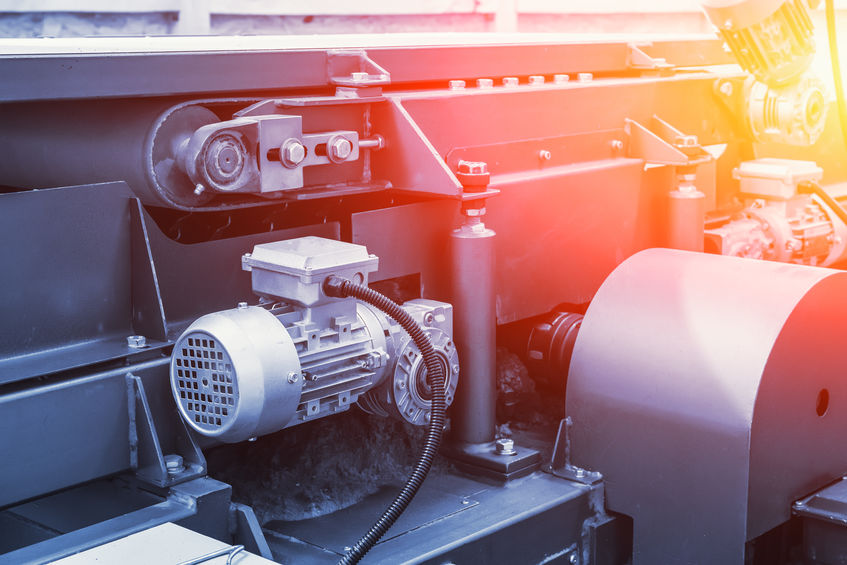

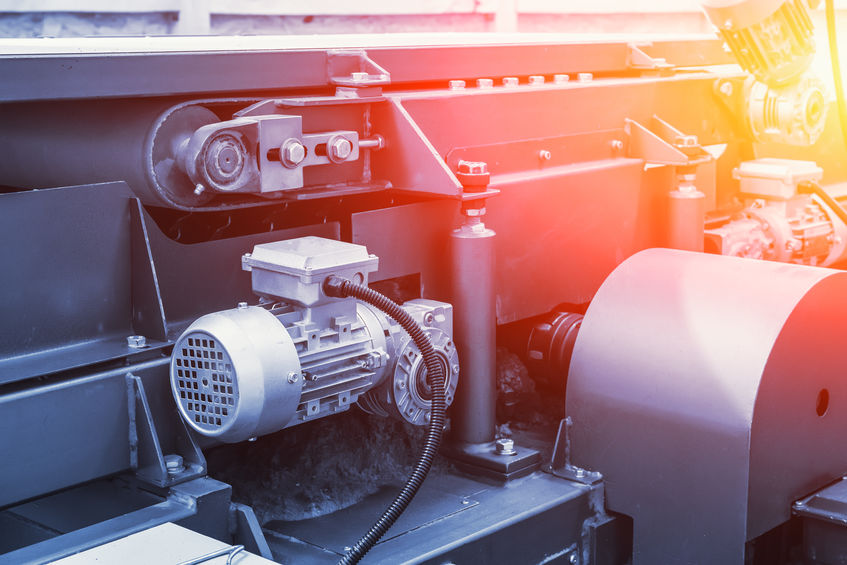

Heavy Machinery

These words usually evoke mental pictures of large yellow behemoths belching black smoke, continuous bellowing accompanied by the shriek and squeal of metal to metal contact and the clink and clatter of track. This equipment is expensive, and can make its owner lots of money if it is working. Often, though, it is neglected resulting in expensive repairs or the replacing of expensive parts long before they should have failed. All this downtime causes a loss of income because the machinery is not operational. The solution is having a good lubrication program for maintaining this equipment and following it.

The program should include a maintenance schedule detailing what needs to be done, how frequently, what lubricant to use, the proper tools to use, and proper training of the people who will do the job.

Too many times people think they are saving money by going cheap to do a job. They fail to look at the impact their efforts to save money really have. Think about it. How much is saved by buying an inexpensive tool that fails or does not work?

The job does not get done in a timely fashion, often the work done needs to be undone before it can be redone. A job that should have taken an hour now takes two to three hours to complete and the machine is unavailable for scheduled jobs or jobs that pop up. Now consider the time lost acquiring another tool to replace the one that failed, and don’t forget the money spent on both of the tools. Surely a tool that cost three times more than the low cost one initially purchased would have been cheaper in the long run.

The point is: EXPENSIVE IS CHEAP in the long run.

Cheap will ALWAYS COST MORE because of overlooked details.

Consider an oil change for a machine with an 11 gallon sump, having an OEM oil change interval of 10,000 miles, that travels 30,000 miles in a year. In the case of diesel engines, most Amsoil diesel oils last three times (3x) the OEM’s oil change interval.

The big cost is the lost revenue due to downtime. What’s your equipment’s hourly rate? If your equipment’s hourly rate is $200, and you lose a five hour job because you can’t get there on time, or you are busy with oil changes that could have been avoided by using a quality product, how much will that oil change cost you?

Industrial Generator

When I first started selling Amsoil 15 years ago one of my first accounts found me through one of the top marine mechanics on O’ahu that many used for repairs on personal and business vessels. The account, The Nature Conservancy, was in the process of looking to acquire two new gensets to supply power to a privately owned remote island wildlife sanctuary on Palmyra atoll. When initially contacted by TNC, I was told that they needed to change oil every 160 hours as per the owner’s manual. The generators they decided to buy were John Deere diesels which provided much more than they needed in kilowatt hours. While one was running, it ran continuously until it reached 160 hours of running time, it was then shutdown after the other had been started.

An oil sample was taken, and then it was drained of its oil, its filter was changed and fresh oil was poured into it. It was then left idle until the other generator reached its 160 hours of running time and the process was repeated. The island was supplied with fresh food supplies and mail by private jet monthly. Large bulky items like outboard motors, and surplus Department of Defense vehicles were shipped in as needed via motor sailors much like something out of Jack London’s Tales of the South Pacific complete with “old salts” that would make a pirate say haaar.

What happened was nothing short of amazing. Running one of the generators for 24 hours and having to change its oil at 160 hour intervals meant changing oil every 6.67 days or weekly. Using oil analysis to be sure the oil in the engines was providing the protection required to not damage the engines, the oil change interval got up to 1,000 hours or 41.67 days before it needed changing. The next big surprise was the amount of waste oil they need to deal with. It went from 15 gallons a month down to 2.5 gallons per month, an 83% reduction.